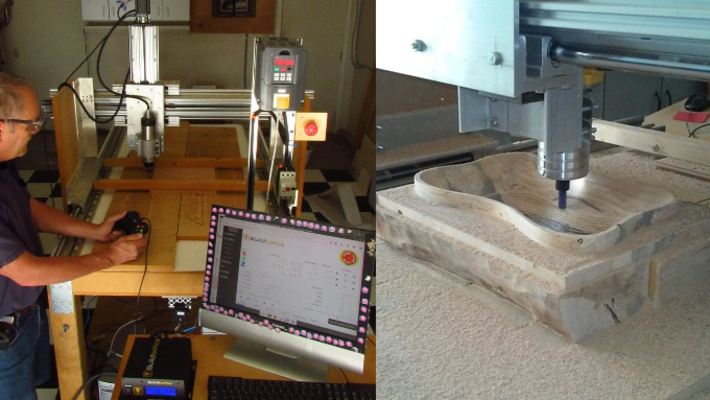

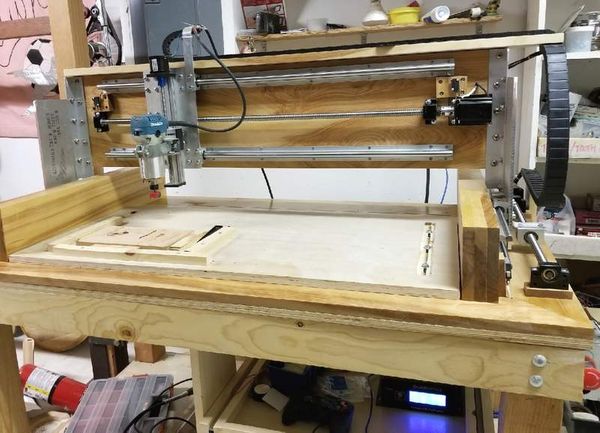

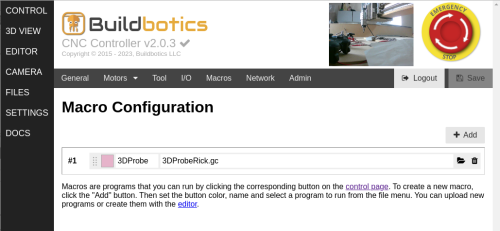

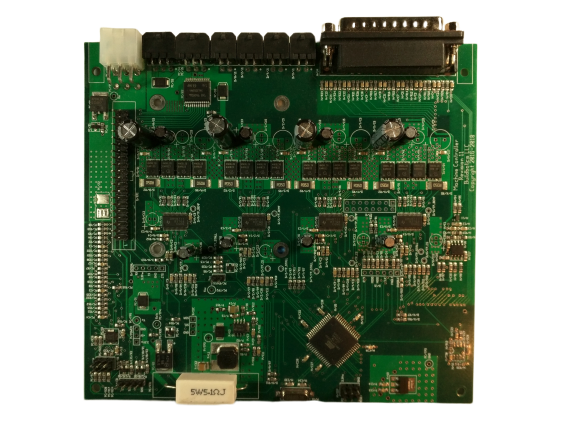

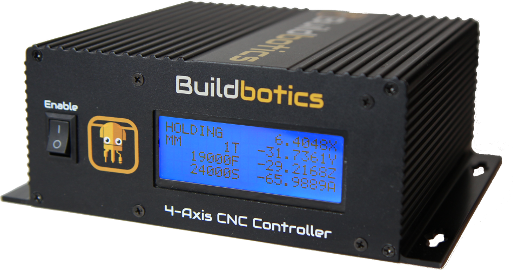

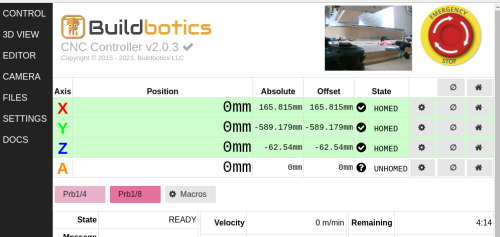

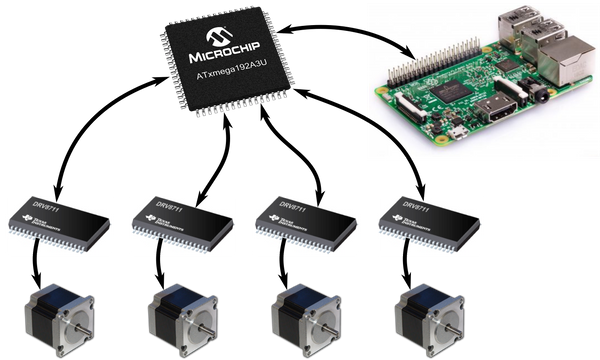

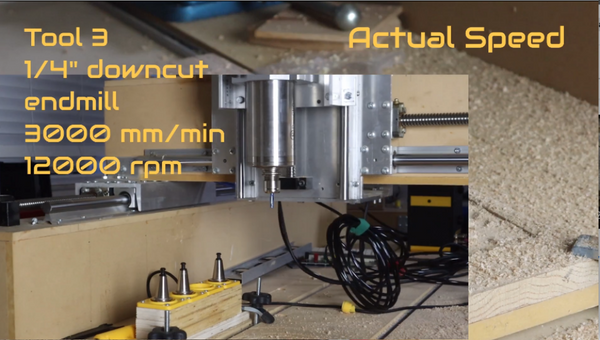

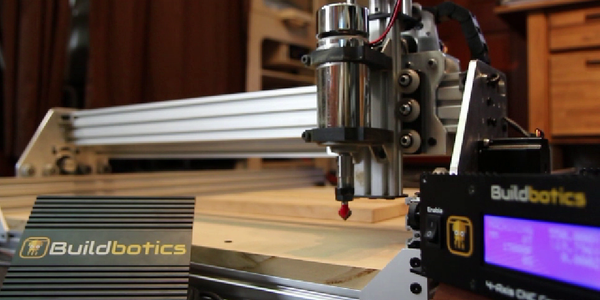

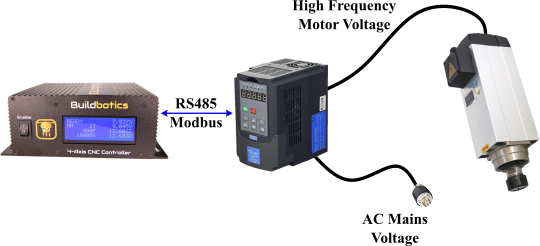

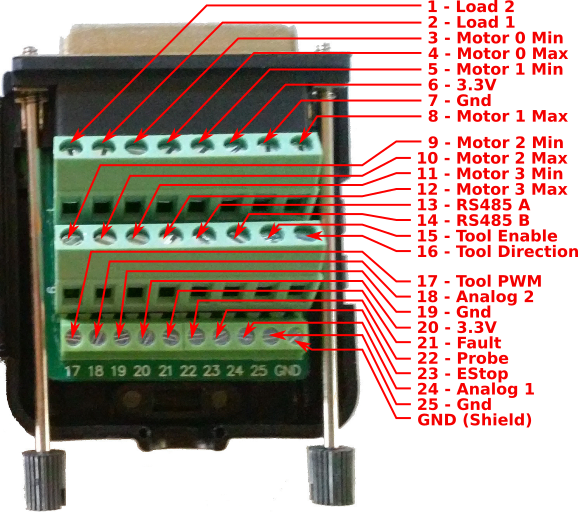

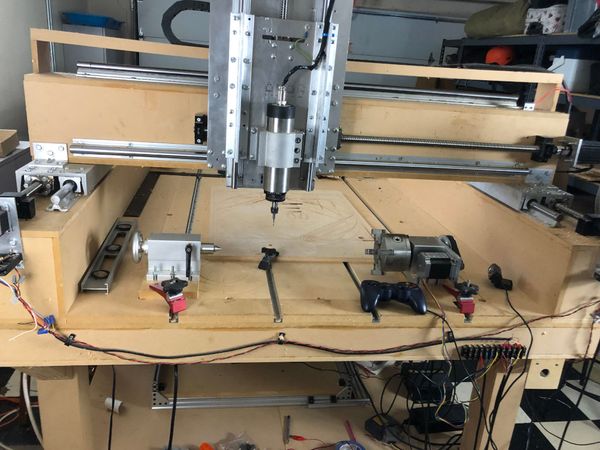

Doug built a custom CNC router using NEMA 23 motors and an air cooled 1.5kW Huanyang VFD spindle. The Buildbotics controller talks directly to the VFD over two wire RS485.

| Cutting Area | 33x47x10in |

| Dimensions | 56x62.5in |

| Motors | 2 x KL23H286-20-8B, 1 x KL232100-36-8B |

| X & Y Axis | 20mm ballscrews, 10mm pitch |

| Z Axis | 16mm ballscrew, 5mm pitch |

To give the CNC extra strength without greatly increasing the weight Doug built a torsion box. You can find the FreeCAD drawings here.

"I found the flattest part of my garage floor, laid a piece of MDF on it to make it even flatter and then started building the torsion box on top of that."